Product Infomation

KAF

prepares for better tomorrow

than today with constant research

and development

Our abundant experience and expertise are recognized throughout the world. KAF is competing with other major companies around the world to become a major global manufacturer.

Staple Fiber

Staple Fiber is a short piece of fiber with crimps.01

KAF's Staple Fiber

KAF produces staple fiber materials by using polymer materials such as Polypropylene(PP), Polyehylene(PE) and Polyethylene terephthalate(PET). In the spinning process, raw material polymers are melted at a high temperature to turn them into thread shapes. This is followed by a drawing process in which spun threads are extended and assigned crimps and functionality.

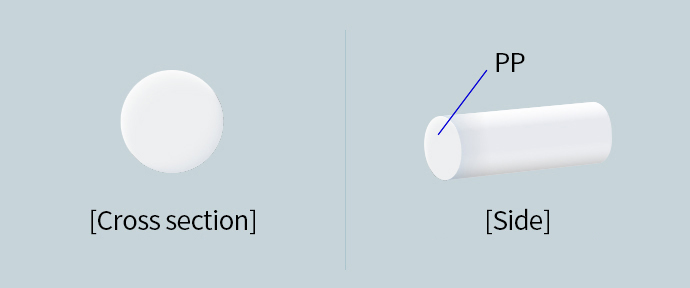

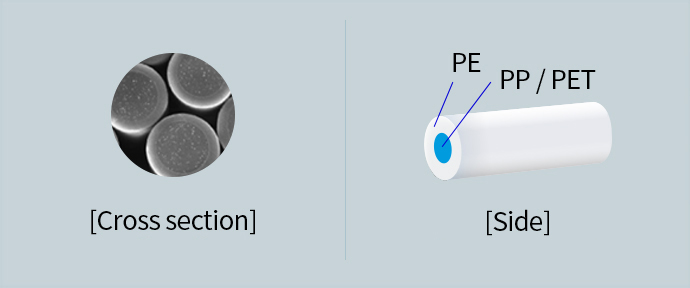

KAF's staple fibers are classified into Polypropylene(PP) Monocomponent staple fiber(single ingredient) and Sheath/Core style Bicomponent staple fiber(dual ingredients). Sheath/Core style Bicomponent staple fibers include PE/PP (polyethylene/Polypropylene) and PE/PET (polyethylene/polyethylene terephthalate) products. These are mainly used as raw materials for non-woven fabrics. Non-woven fabrics made of staple fibers are very soft and bulky.

02

Polypropylene(PP) staple fiber

03

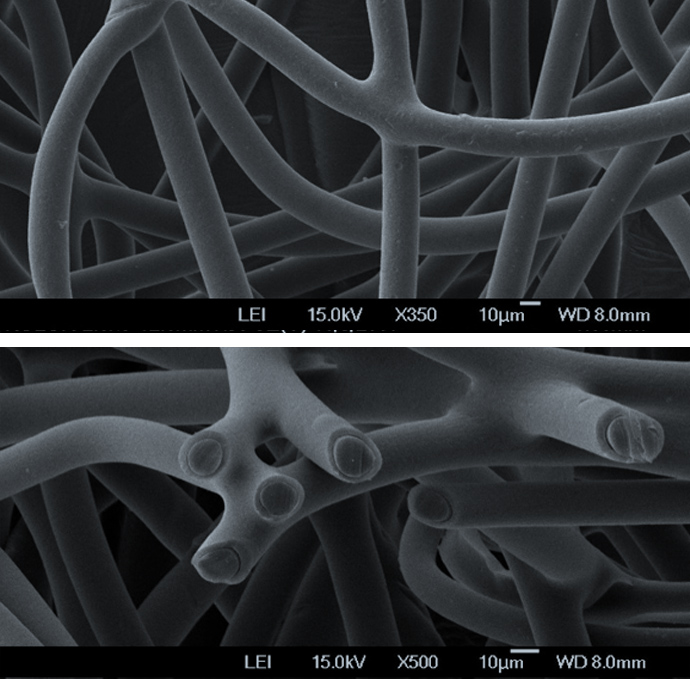

Sheath/Core style Bicomponent staple fiber

Application

The staple fibers manufactured by KAF are mostly processed into non-woven fabrics; in some cases, they are processed into yarns.01

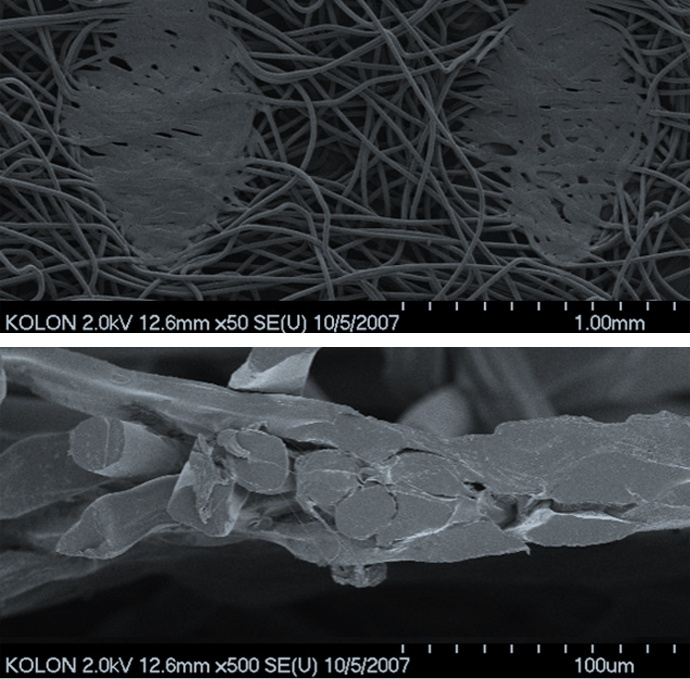

Thermal point bonded nonwoven

Calender roll’s embo pattern leads to successful point bonding. As a result, flat and smooth products are created.

02

Air-through bonded nonwoven

Hot air in the oven melts the overall sheath to perform bonding. As a result, bulky and soft products are created.

Product information

Move the screen from side to side.

| CATEGORY | DENIER | LENGTH | PROPERTY | MAIN APPLICATION | REPRESENTATIVE ITEM |

|---|---|---|---|---|---|

| THERMAL BOND | 2.0 - 10.0 | 40 / 45 / 51 / 64 / 76 |

DURABLE H/Philic HYDROPHILIC HYDROPHOBIC |

DIAPER SANITARY NAPKIN WIPES |

KSS-700 (2.0X40) KSS-790 (2.0X40) KSS-790 (2.0X40) |

| SPUNLACE | 1.5 - 5.0 | 40 / 45 / 51 |

HYDROPHILICc (LOW FOAMING) |

WIPES |

SPL-150 (1.5X40) SW-1001 (1.5X40) |

| NEEDLE PUNCH | 1.5 - 10.0 | 40 / 45 / 51 / 64 / 76 |

HYDROPHILIC HYDROPHOBIC |

OIL ABSORBENT AIR FILTRATION CAST |

P-4500 (7.0X64) |

| SPINNING | 1.5 - 6.0 | 40 / 45 / 51 / 64 | HYDROPHILIC | SPUN YARN |

P-1006 (6.0X60) P-6408 (2.0X40) |

| CATEGORY | DENIER | LENGTH | PROPERTY | LUSTER | MAIN APPLICATION | REPRESENTATIVE ITEM | ||

|---|---|---|---|---|---|---|---|---|

| PE/PP | AIR THROUGH | CENTRIC | 1.5 - 10.0 | 40 / 51 / 64 | DURABLE HYDROPHILIC HYDROPHOBIC |

FULL DULL SEMI DULL BRIGHT |

DIAPER SANITARY NAPKIN AIR FILTRATION MEAT PAD TEA BAG |

KEP-32F (2.0X40) KEP-22B (2.0X40) AFP-120B (2.0X40-51) HP-150HB (5.0X51, ECCENTRIC) |

| ECCENTRIC | 5.0 - 15.0 | |||||||

| THERMAL BOND | CENTRIC | 1.5 - 15.0 | 40 / 51 / 64 | DURABLE HYDROPHILIC HYDROPHOBIC |

FULL DULL SEMI DULL BRIGHT |

DIAPER MASK MEAT PAD |

KEP-32B (2.0X40) KEP-33B (3.0X40) KEP-215S (1.5X40) |

|

| SPUNLACE | CENTRIC | 1.5 - 6.0 | 40 / 51 / 64 | HYDROPHILIC | FULL DULL SEMI DULL BRIGHT |

DIAPER SANITARY NAPKIN WIPES |

KEP-12B (2.0X51) | |

| PE/PET | AIR THROUGH | CENTRIC | 1.2 - 10.0 | 40 / 51 / 64 | DURABLE HYDROPHILIC HYDROPHOBIC |

FULL DULL SEMI DULL |

DIAPER SANITARY NAPKIN AIR FILTRATION |

KET-32F (2.0X40) KET-22SD (2.0X40) KET-15SE (5.0X51, ECCENTRIC) AIR FILTRATION (3.0-8.0X40-51) |

| ECCENTRIC | 2.0 - 8.0 | |||||||

| SPUNLACE | CENTRIC | 1.2 - 6.0 | 40 / 51 / 64 | HYDROPHILIC | FULL DULL SEMI DULL |

DIAPER SANITARY NAPKIN |

KET-12MS (2.0X51) KET-15MS (5.0X51) |

|

| CATEGORY | APPLICABLE ITEM | DENIER | LENGTH | APPLICATION | |

|---|---|---|---|---|---|

| SPECIALTIES | MENSTRUAL BLOOD HIDING EFFECT |

PE/PET | 2.0 - 6.0 | 40 / 51 / 64 | SANITARY NAPKIN |

| DEODORANT | PP, PE/PP, PE/PET | DIAPER SANITARY NAPKIN WIPES |

|||

| WEAK ACID | PP, PE/PP, PE/PET | DIAPER SANITARY NAPKIN |

|||

| SKIN CARE | PP, PE/PP, PE/PET | DIAPER SANITARY NAPKIN |

|||

| BIODEGRADABLE [Biolefin] |

PP, PE/PP | WIPES DIAPER SANITARY NAPKIN INDUSTRIAL |

|||