01

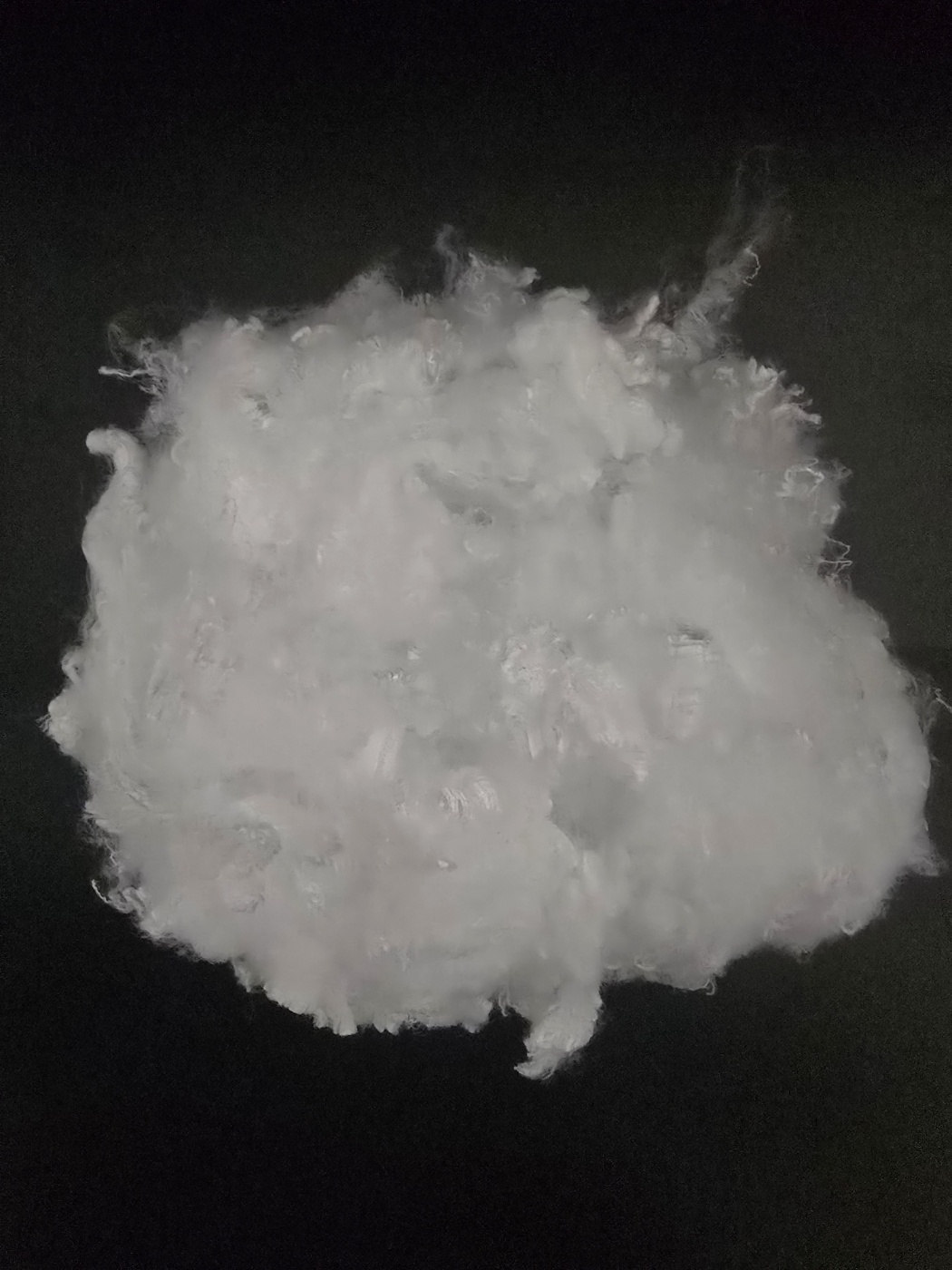

KAF's Staple Fiber

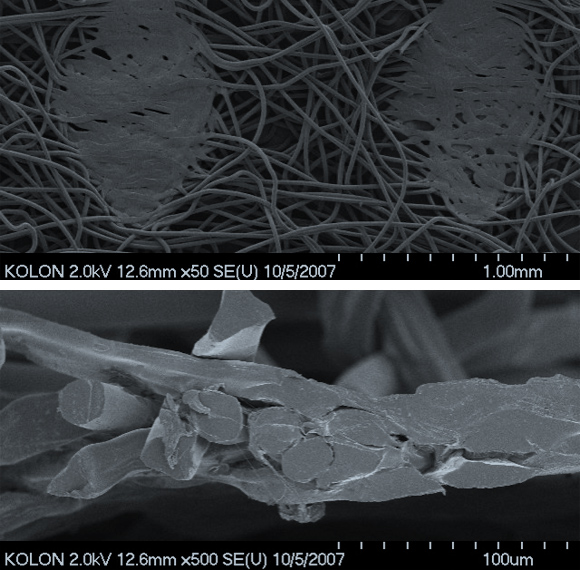

KAF produces staple fiber materials by using polymer materials such as Polypropylene(PP), Polyehylene(PE) and Polyethylene terephthalate(PET). In the spinning process, raw material polymers are melted at a high temperature to turn them into thread shapes. This is followed by a drawing process in which spun threads are extended and assigned crimps and functionality.

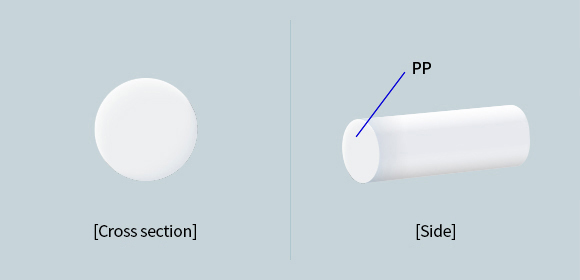

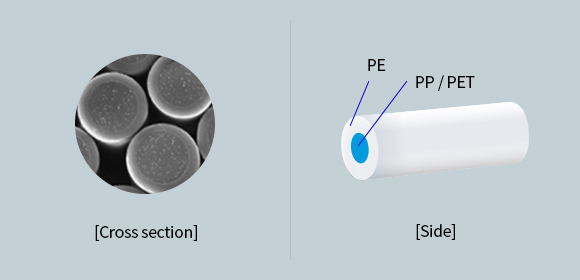

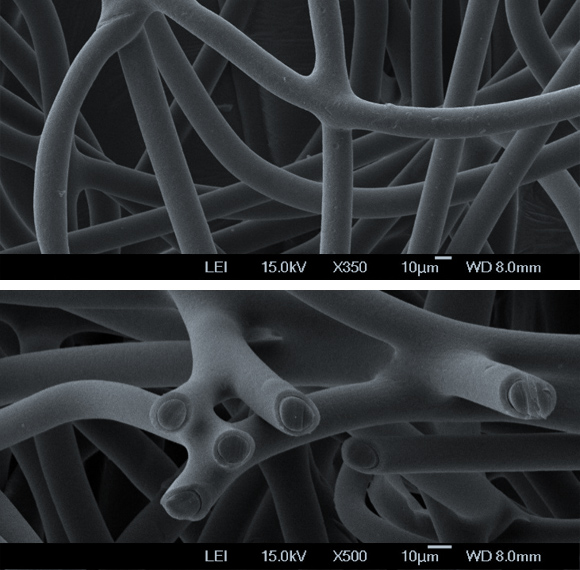

KAF's staple fibers are classified into Polypropylene(PP) Monocomponent staple fiber(single ingredient) and Sheath/Core style Bicomponent staple fiber(dual ingredients). Sheath/Core style Bicomponent staple fibers include PE/PP (polyethylene/Polypropylene) and PE/PET (polyethylene/polyethylene terephthalate) products. These are mainly used as raw materials for non-woven fabrics. Non-woven fabrics made of staple fibers are very soft and bulky.